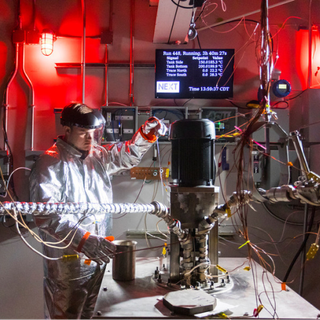

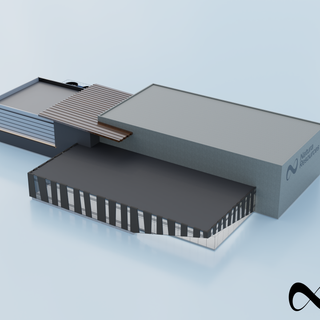

Natura Resources recently commissioned a 50-gallon molten salt test loop dubbed the Molten Salt Test System (MSTS) at Abilene Christian University (ACU). The system will operate with FLiNaK salt procured from Materion and Copenhagen Atomics and will be utilized as a test bed to validate materials, components, and operations in support of the Natura MSR-1 deployment at ACU.

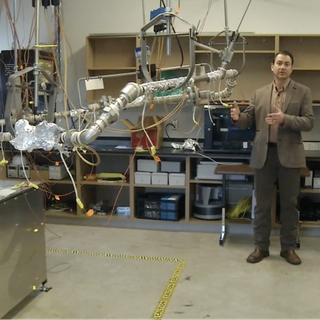

The system was designed by a team of staff and students at ACU under the guidance of Natura Resource's engineering team and was fabricated in large part using local Abilene businesses such as Hartmann's Inc. and Rentech Boilers. The MSTS includes several removable sections that enable the installation of different components for testing in a 600+ degree Celcius flowing salt system.

Included as part of the MSTS is a 50-gallon salt purification system known as the Fluoride Salt Purification system (FSP) that performs large-scale hydrofluorindation of the FLiNaK salts in the MSTS.

"We are thrilled that operations have begun on the MSTS. This is another example of the step-by-step systematic approach that Natura has taken to deploy liquid-fueled molten salt reactors to meet our nation's needs for clean energy, clean water, and medical isotopes. With this test system, we are going to be able to verify and validate critical components such as valves, flanges, pumps, and instrumentation that we have already implemented into the design of the Natura MSR-1 system," says Jordan Robison, VP of Engineering and Program Management for Natura Resources.

%20Dr.%20Phil%20Schubert_John%20Zachry_Douglass%20Robison_Dr.%20Rusty%20Towell.jpg?rect=49,0,1269,1269&w=320&h=320&fit=min&auto=format)